News: PRP Announces New Audio Quality Assurance System

By Simon Daley

Precision Record Pressing announces a new industry leading audio quality assurance system.

Earlier this year, our team in Burlington Ontario began testing and training on a brand new software system that we call AQA. This Audio Quality Assurance software allows us to partially digitize PRP’s quality control process, greatly reducing the potential for human error and enabling digital record keeping and instant referencing for any issues that may arise during a production run.

So how does it work?

The system uses a powerful combination of audio analysis, visual inspection and machine learning to identify potential issues during the pressing process and alert our team when action needs to be taken. In keeping with our traditional quality assurance process, the first pressed copy of an order is collected by the quality control team to be listened to in full.

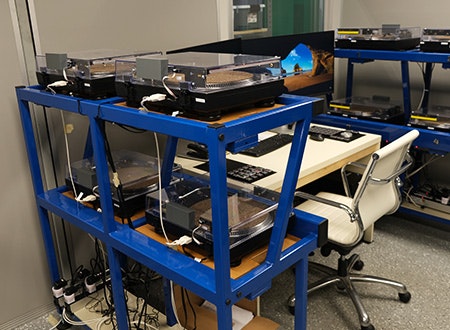

With our new system, the second pressed record is also taken to the quality assurance department for analysis. Both records are simultaneously placed onto heavily modified turntables that are digitally controlled. First the computer uses surface scanning cameras built into the lid of the turntable to automatically scan both records for any defects or areas of concern.

Next the computer automatically synchronizes both turntables to ensure they are playing at the same speed and listening to identical passages of music at the same time. The system then records the entire side of both records and in real time compares them to the digital master that we have on file.

Without interrupting the system’s recording process, our quality control team can simultaneously troubleshoot any issues that are detected and determine whether they are either serial concerns or isolated to an individual copy. If the issues are serial, the pressing will be stopped to allow the problem to be investigated, isolated and resolved. If the identified issues are confined to an individual copy, we can be confident that they won’t recur in future.