Guide: Direct Metal Mastering (DMM)

By Simon Daley

Once you have finished recording, mixing and pre-mastering your project, the next step is to transfer your digital audio to a physical format. This step is called ‘cutting a master’ and can be done using one of two methods: lacquer or DMM. Below we compare the two options and their respective characteristics.

Since 1983 two methods of bridging the digital and physical mediums in preparation for vinyl record pressing have been available to record labels and artists. Direct Metal Mastering, better known simply as DMM was jointly developed by two German companies as an alternative to the well established process of Lacquer Mastering, which had previously reigned unchallenged for decades.

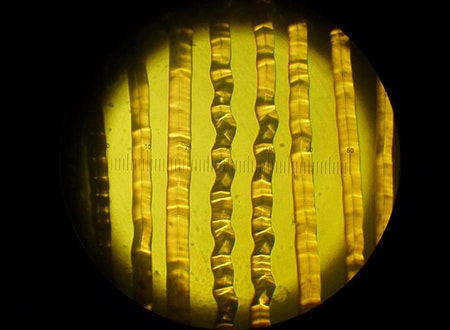

While lacquer mastering consists of a lathe cutting grooves into a soft lacquer-coated aluminium disc, DMM uses an alternative style of lathe with a diamond cutting head that cuts grooves into a steel disc coated in high purity copper.

One of the key advantages of cutting into copper is the ability to skip two stages of the electroplating process that follows cutting. This includes the “silvering” wash to make the lacquers electrically conductive and a second step of electroplating to create a backup of the lacquer. Since DMM cutting avoids both of these stages, the risk of introducing greater surface noise is reduced.

One advantage of lacquer cutting is that it has the capability of producing louder sides, since you can cut deeper into the soft surface of a lacquer disc compared to a hard copper DMM blank. This may appeal to those cutting 12″ club singles or LPs with shorter sides. However, it should be noted that loudness isn’t without risk, as it can induce distortion or skipping on some turntables.

Since lacquers aren’t perfectly flat, it’s necessary for an engineer to cut a wider groove to avoid the risk of skipping issues during playback. These wider grooves result in a shortened playback time per side on lacquer cut projects. This issue is mitigated with DMM cutting as the copper layer on the disc is flat and therefore allows the engineer to cut a 20% narrower groove, which results in a longer cutting time. Therefore with DMM we are able to safely fit up to 6 minutes of audio per side on a 7” (at 45 RPM), 15 minutes on a 10” (33 RPM) and 22 minutes on a 12” (33 RPM), depending on the genre of the recording. Longer sides are also possible with the risk of incurring some distortion. Speak to your account manager for more information.

Another advantage that DMM cutting offers over the lacquer process is the reduced risk of a phenomena called “pre-echo” or “print-through”. During the lacquer cutting process the lathe stylus often increases in temperature and subsequently increases the surface temperature of the lacquer disc. A consequence of this is that when a loud section of audio follows a quiet passage on a lacquer, the stylus can inadvertently copy the loud signal onto the previous quiet groove, causing an effect known as pre-echo. DMM cutting does not suffer from these same limitations as the stylus is able to maintain a stable temperature during cutting.

Finally some labels consider the environmental impact of lacquers when deciding which cutting route to take for their project. While processed lacquers are predominantly single use due to their delicate properties, DMM copper blanks are 100% recyclable for repeat use. DMM also requires less chemicals and energy due to the skipped silvering and electroplating stages mentioned earlier.

Since each method has its own set of strengths, the decision to cut DMM or Lacquer is a subjective one based on preference, genre, and style. At Precision Record Pressing, we maintain DMM as our preferred and default option, due to its ability to cut longer sides and reduce the risk of surface noise. We are also happy to provide lacquer cutting and receive cut lacquers from your chosen mastering studio. Half-speed DMM cutting is also available upon request for an additional charge and is only recommended for audio cut at 45RPM. Please speak to your account manager for more information.